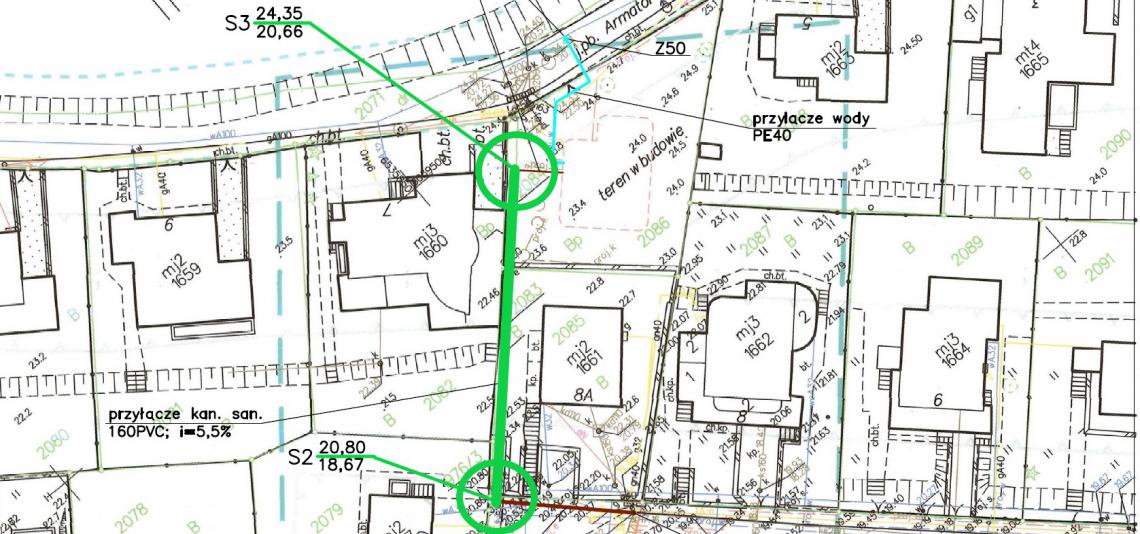

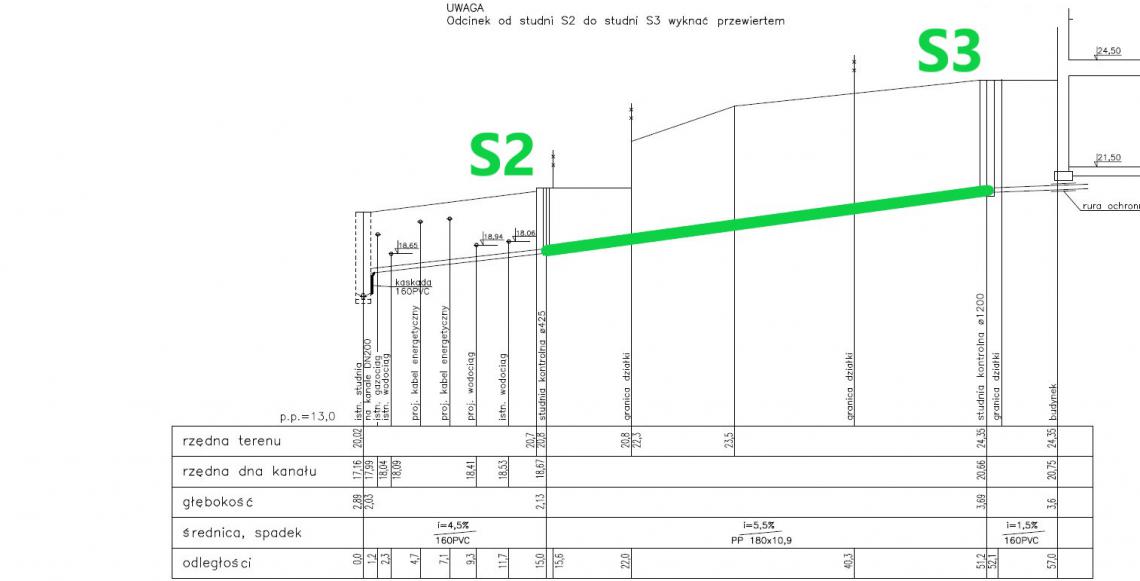

The Gravity Drilling Technology also includes installations made of PE pipes. One of such projects was the construction of a sanitary sewage connection for a single-family residential building in the Redłowo estate in Gdynia. The installation of the PE-RC DN160 pipe should be 37 meters long, with a 5.5% gravity drop, between the existing DN1200 well and the excavation.

In the case of this project, it was difficult to locate the installation among dense residential buildings and home gardens. In the area of work, there was a significant slope of the terrain and slopes limiting the maneuvering of any construction equipment.

Initially, it was assumed that the installation would be performed with the use of a HDD drilling rig, but due to the above-mentioned field inconveniences, the company declaring execution with the use of HDD eventually withdrew from the implementation after an on-site visit. The installation was considered with the use of a pneumatic jacking machine, commonly known as a mole. However, there was a high risk that the jacking technology, uncontrollable and without the possibility of locating and possible corrections of the set trajectory, on a length of 37 meters, would fail, the mole would not hit the well, we would not get the desired drop. In addition, vibrations and shocks caused by the mole's work may cause damage to neighboring buildings and other facilities such as retaining walls and brick fences. We know of projects in which the use of a mole for a typical culvert under the road caused damage, cracks in the facades of buildings adjacent to the works. The strength of such an impact can be approximated on the basis of the ability to transmit vibrations through a given soil medium, but it is associated with additional expertise and soil tests. The use of a mole in such a close development is a high risk related to possible claims for possible damage. Moreover, such work would be very troublesome. It was impossible to install the installation using an open trench, due to the co-location of the installation with a 1.5 meter wide technical belt belonging to the city. In the end, it turned out that the technology with the use of the Gravity Drilling Rig is the only effective and most economical solution for this project.

The advantage of the Gravity Drilling technology, apart from the efficiency in drilling and accuracy in the implementation of precise installations, is also the mobility of the devices included in the drilling set. All devices are placed in a compact car body. This allows you to carry out work virtually anywhere, even densely built-up and with difficult access.

You can read about other selected projects by clicking on the picture below: