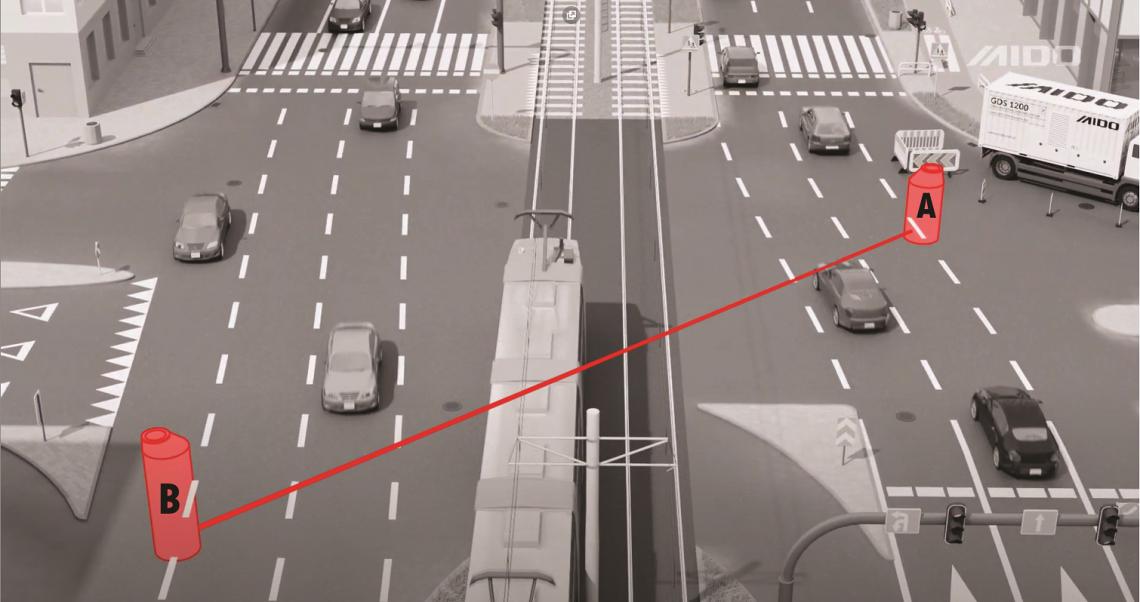

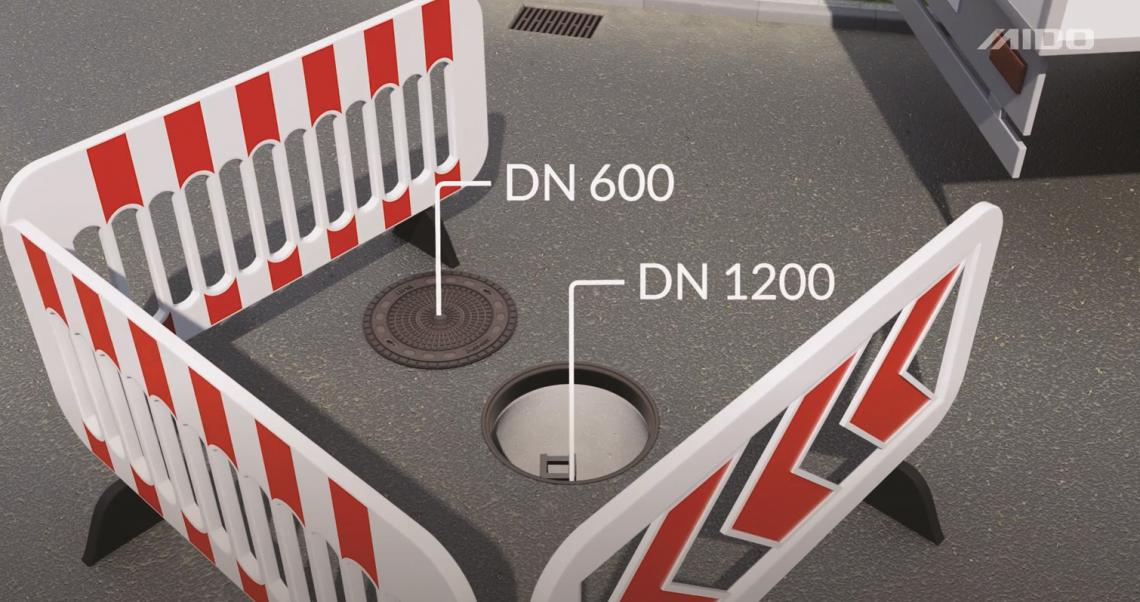

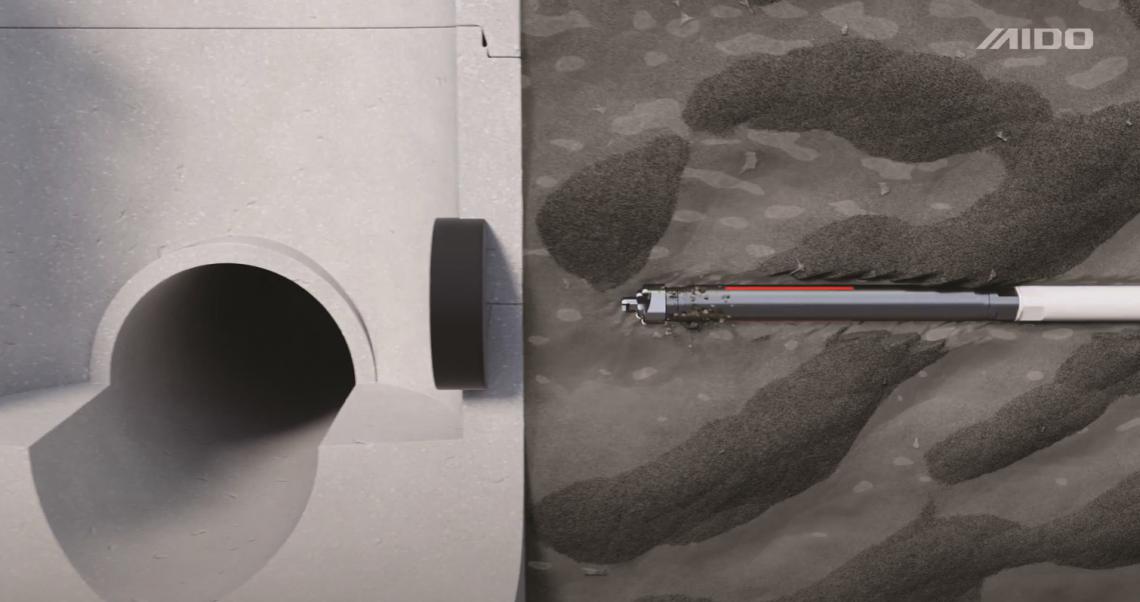

The technology of Gravity Drilling allows for fully trenchless and completely non-invasive implementation of water and sewage systems in the existing infrastructure. This applies in particular when it is necessary to install an installation between the existing sewage chambers. The small dimensions of the drilling device allow it to be inserted through a typical DN600 manhole and installed in typical DN1000 DN1200 and DN1500 manholes. The implementation of installations between non-standard dimensions and sizes of wells is also possible, thanks to the use of a portable starting chamber and adapters in which the drilling rig is installed. Installation in wells and low mechanical strength is possible. Our technology allows us to build a network regardless of ground conditions and depth. The presence of groundwater is not an obstacle. The precise location system, together with the innovative drill head system, allows the installation to be made with the highest possible accuracy, reaching 0.2%. Most often, the Gravitational Drilling Rig is used to perform the installation between the typical DN1200 wells most commonly used in densely built-up urban agglomerations. The new installation is made from the starting well (A) to the final well (B) using the trenchless method, without any additional excavations and demolition of the surface. It is only necessary to fence the lane at the site of the well location.

The construction of the machine enables its introduction through a typical DN 600 manhole. The new network is made from DN 1000 and larger manholes.

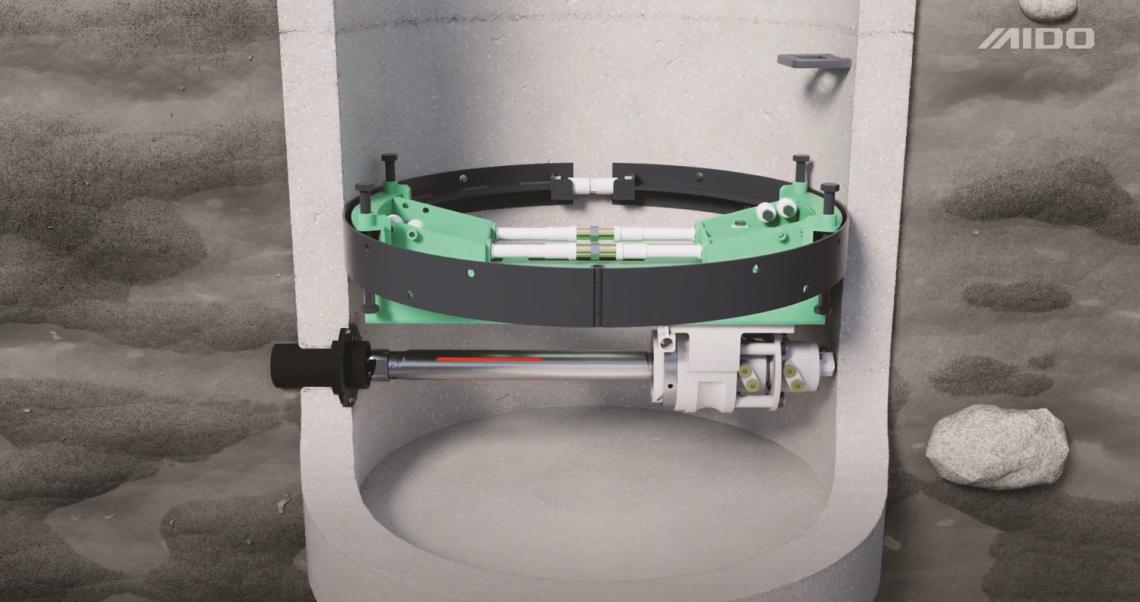

Our solution ensures quick preparation of the machine to work. The drilling rig is assembled by inserting the device into the well with a lifting device and fixing it on special hoops. The structure of the machine has been designed in such a way as to minimize the assembly and disassembly process at the work site. This significantly reduces the time of installation, which shortens the time of possible occupation of the lane on which it takes place.

The installation can be performed in any place of the well: directly under the cover of the well, at the level of the well bottom or directly from the base plate, without the need to disassemble the landing or without deepening the well bottom.

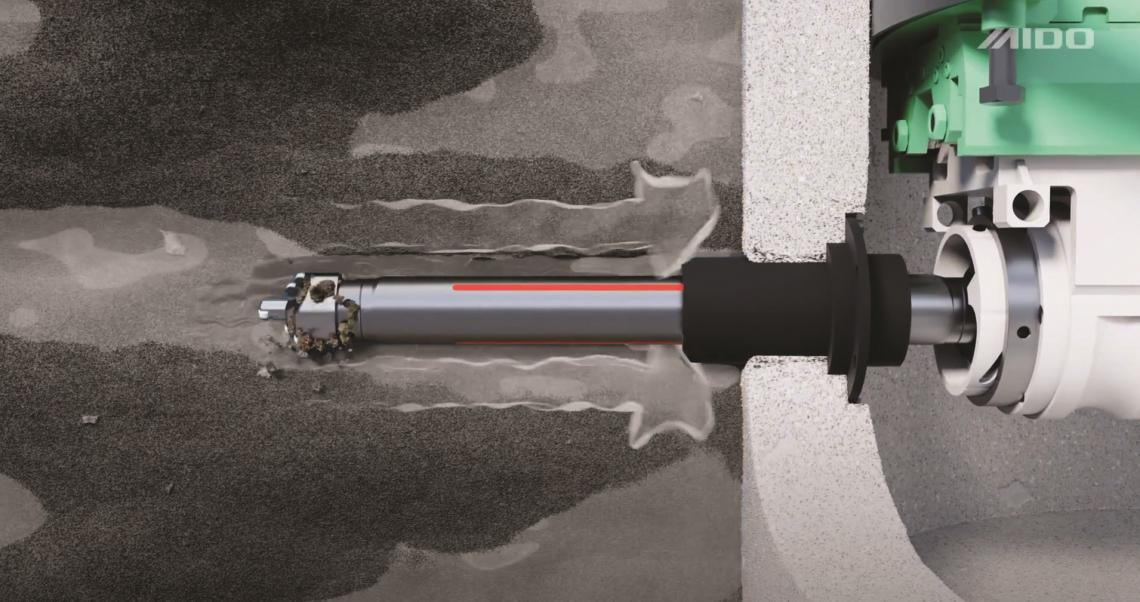

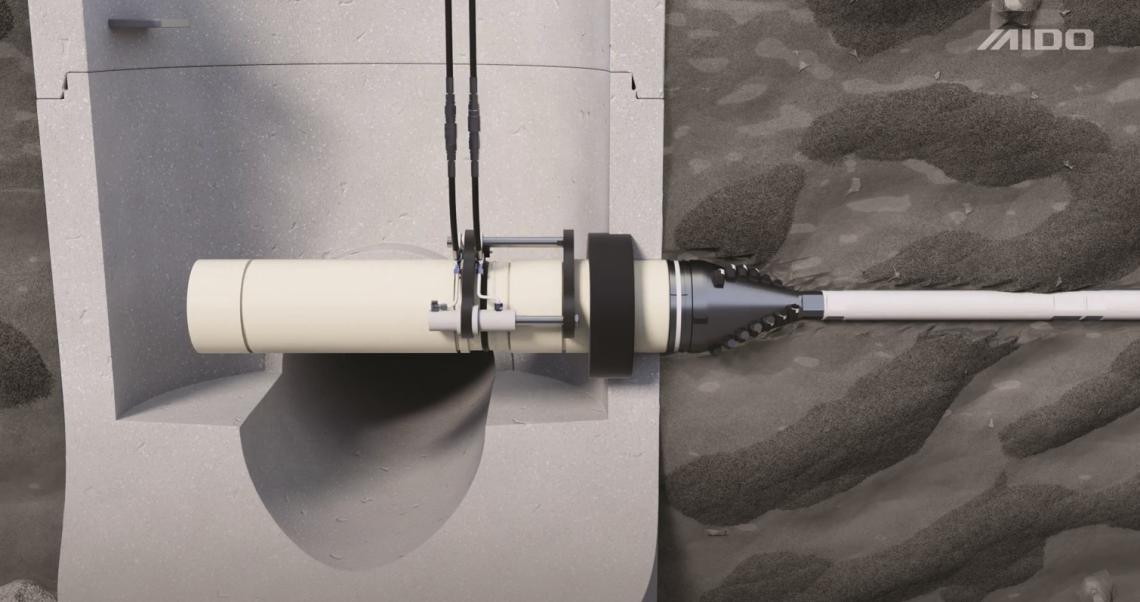

In order to prevent the penetration of groundwater into the well, we use preventers, i.e. sealing systems. We use sealing systems both in the starting and ending wells. They prevent groundwater from penetrating into channels and sewage into the surroundings around the implemented installation. Works using technology do not require additional drainage installations. Years of experience have enabled us to develop an effective well sealing system at the point of drilling through its walls. Thanks to the sealing system, we can perform installations in soils with numerous groundwater.

Our technology allows you to make networks without blocking the flow of sewage. Drilling is possible in soils with drilling classes: II, III, IV, V (sand, gravel, clay, soft and medium rock).

The sewage system is made of Modular Pipes. Modular pipes are connected by means of a compact squeezer, adapted to each pipe diameter. The total length of the modular pipes including the introducing and expanding pins is 700 mm. Longer modular pipes with a length of no more than 1000 mm can be made. The tightness of the connection of individual modules is achieved by a gasket made of NBR.