None of the so far known, developed and used no-outlet technologies have as many features and advantages as in the case of our gravity installation technology. Many underground installations can only be made with our Gravity Drilling Rig.

Our advantages:

-

the starting chamber is a well (new or existing) DN 1000, DN 1200 or larger

-

works can be performed from typical sewerage chambers, without the need for any interference with the existing buildings or surface

-

the possibility of implementing installations from typical wells without the need to interfere with the surrounding infrastructure

-

the drilling machine is placed in the well through a typical DN 600 manhole

-

the execution of the installationl does not require any excavation, the work begins and ends in the wells

-

no need for starting chambers and their drainage

-

the possibility of mounting the machine in wells of any non-standard shape and working from the excavation using a mobile starting chamber and / or adapters

-

the ability to perform work from a starting well with low mechanical strength

-

the possibility of working in a well equipped with space-limiting elements without the need to disassemble them

-

it is possible to drill at any depth

-

the technology allows to make installations with an accuracy of 2 ‰ (depending on the soil)

-

the drill spindle can work close to the bottom and under the cover of the well

-

drilling possible below groundwater level. This applies to the entire boring route also to the area around the well

-

work in soils with drilling classes: II, III, IV, V (sand, gravel, clay and soft rocks, medium: marly limestones, order clay, marls, sand shales, rubble, concrete obstacles)

-

the technology does not reduce soil compaction, and even allows to thicken the zone around the pipe to be laid

-

when drilling works on active collectors, there is no need to block sewage

-

the highest efficiency of the installation compared to other available trenchless technologies

What is the reason for such high efficiency and the ability to drill in difficult ground conditions, also in the presence of boulders, debris and concrete obstacles, without losing the set direction? The solution on which we have worked for years and which we have been using for several years is the use of a double drive system in our drilling rig. Below we will discuss some of the most important features / advantages of our technology.

ACCURACY AND PRECISION

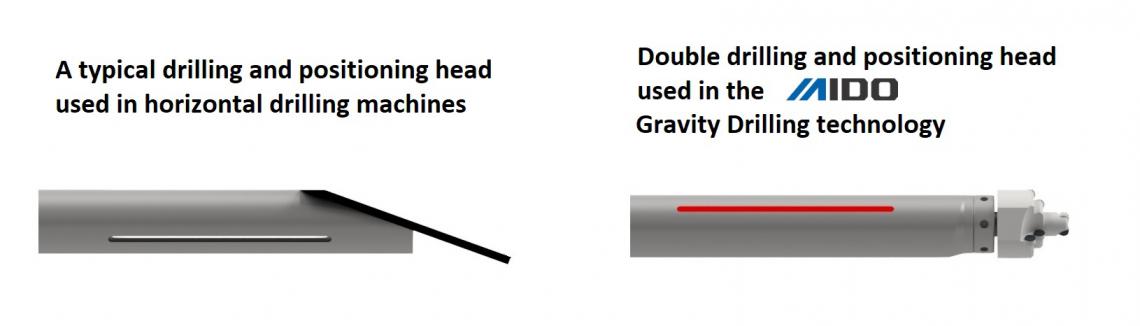

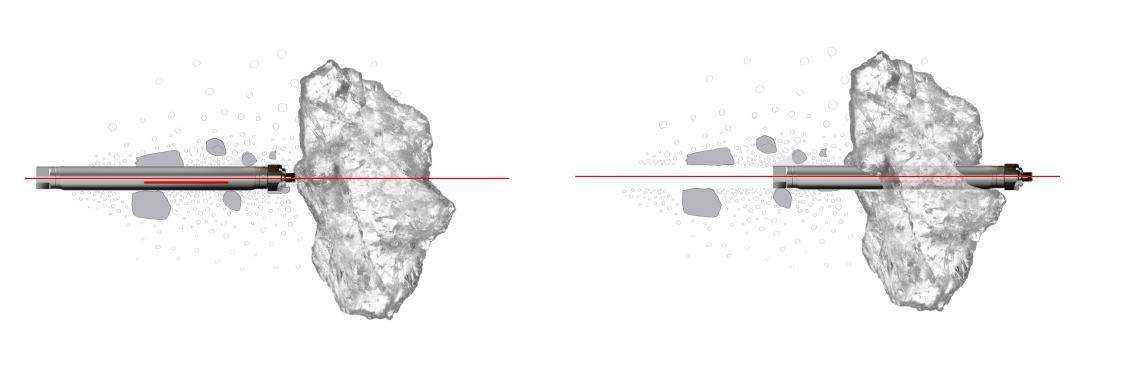

The illustration below shows schematically how the heads used for pilot drilling, which are performed as the first stage of building an underground sewage system, are constructed.

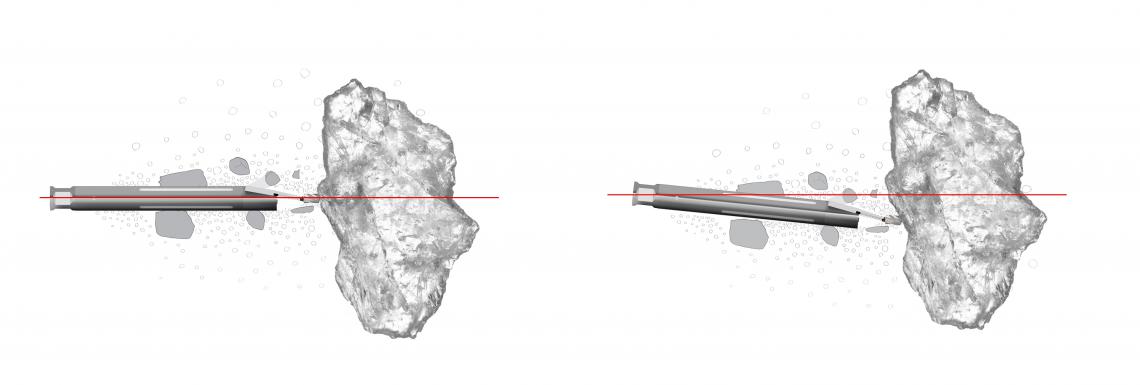

Most technologies and machines intended for horizontal drilling, e.g. HDD drilling rigs, use single drives working with single drilling heads. Such a single head includes both cutting elements and head positioning elements. Such a head has only one rotary drive which simultaneously performs drilling in the ground and allows for controlling the direction of the drilling. In typical soils, lacking large and hard fractions, a typical head will handle the drilling without losing the set direction. The problem will arise when a hard obstacle is encountered while performing a pilot drilling. A single head with a single drive will have difficulty drilling through such an obstacle and either fail to drill through the obstacle at all, or will overcome it having lost the desired drilling direction. The head, which contains both elements responsible for drilling and control, does not have full and effective drilling properties.

The scheme of such action is presented below.

The effect of changing the drilling direction will be a change in the planned and required gravity drop of the installation being performed, which usually excludes a positive reception of the work performed by the client / investor. In an extreme situation, the obstacle cannot be overcome.

The solution to this problem is to use a device with a double drive, i.e. two independent head drives. In our Gravity Drilling technology, we have used our innovative dual drive system, in which one drive is responsible for drilling in the ground, and the other drive controls the direction of the drilling. The illustration below shows schematically the solution of the double head drive.

The use of a double drive allows you to overcome almost all obstacles in the ground, without the risk of losing the set direction. We can be sure that the completed installation will have a predetermined and precise gravitational drop.

TRENCHLESS IN ALL CONDITIONS

Very often we have to deal with a situation where another potential installation contractor, after a site visit, resigns from undertaking the construction works. The reason is usually the inability to install with the machines due to limited space. Any other trenchless devices, precision drilling rigs or jacking machines require large working chambers, which would entail the necessity to exclude entire communication routes from traffic. To work with our controlled drilling technology, we only need the starting well, DN1000, DN 1200 or DN1500, or an area / chamber the size of such wells, to install our device directly in the well or in the chamber, by using an appropriate adapter.

Awards and distinctions: